| Exterior Finish |

Standard palettes, custom RGB, texture and gloss selection. |

Align visual identity with your brand series. |

| Drawer Layout |

7-13 drawer architecture, mixed-width columns, top compartment ratio. |

Match local user habits and tool set profile. |

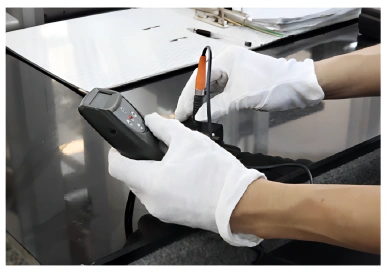

| Lock System |

Recessed standard lock or smart lock with keypad and fingerprint. |

Balance security level and product positioning. |

| Brand Placement |

Right-side badge area, logo plate, carton marking, and instruction artwork. |

Improve shelf recognition and channel consistency. |

| Integrated Power Module |

Upper side-mounted PDU + USB with US, UK, EU, AU plug standards. |

Fit market regulations and workshop usage. |

| Mobility System |

Caster material, brake type, wheel size, and load matching. |

Ensure stable movement under actual payload conditions. |